- | /

- | /

- | /

- | /

- | /

- | /

Medical Device Machining: The Fine Choice of CNC Machine Tools

I. Special Requirements for Medical Device Machining

Medical devices are directly related to people's lives and health, so their machining processes have extremely high standards and special requirements. Firstly, the components of medical devices usually have complex geometric shapes and fine structures. For example, a cardiovascular stent needs to have an exact diameter and a complex mesh structure to ensure that it can successfully expand the blood vessels and provide good support inside the body. Secondly, the machining precision is required to reach the micron or even sub-micron level, as any tiny error may affect the performance and safety of medical devices. For example, the surface roughness and dimensional precision of artificial joints directly affect their adaptability to human bones and the stability of movement. In addition, medical devices are made of various materials, including stainless steel, titanium alloy, ceramic, etc. These materials have different hardness, toughness, and machining characteristics, which require appropriate machining processes and equipment to handle.

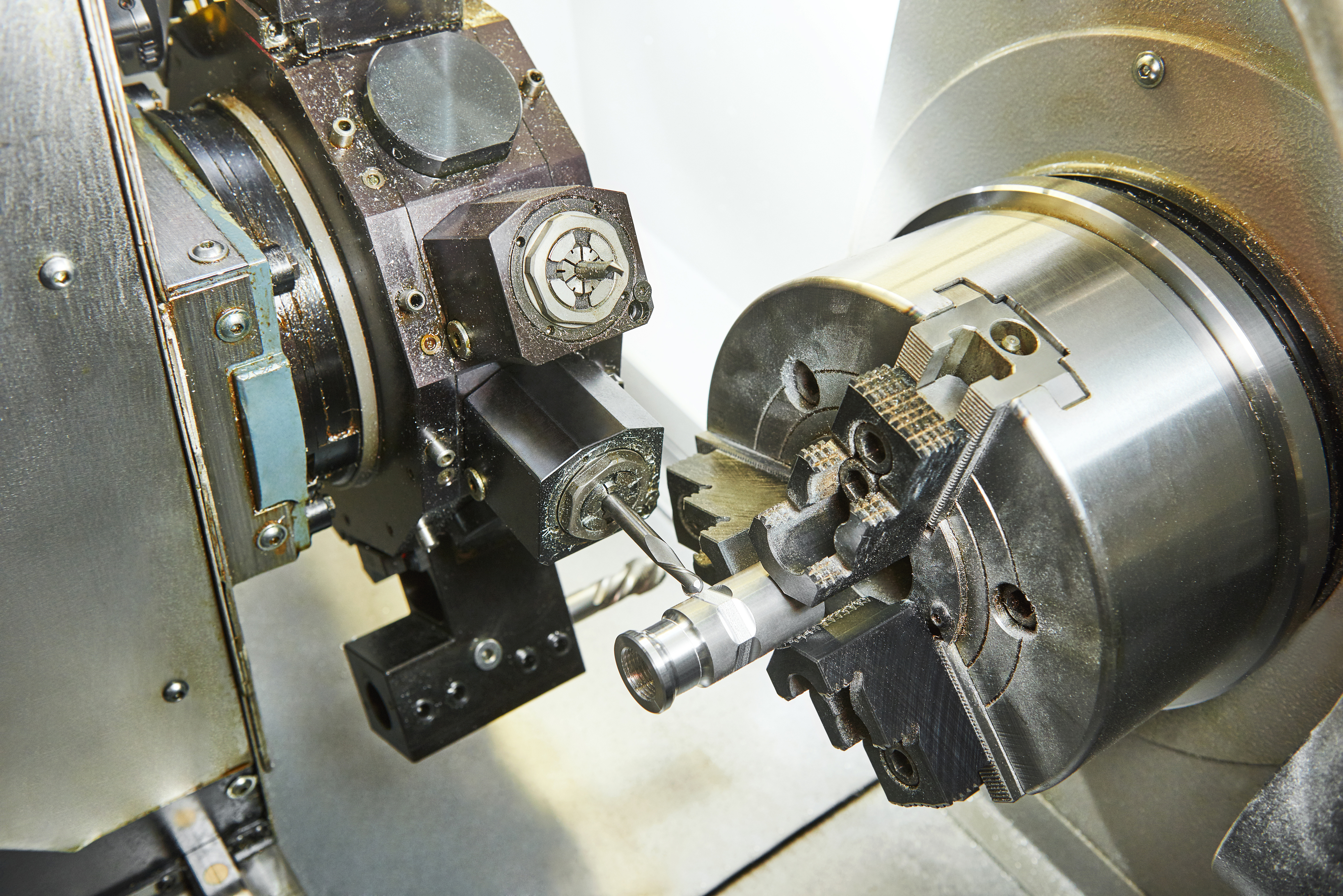

II. Advantages of CNC Machine Tools in Medical Device Machining

High-Precision Machining Capability

CNC machine tools adopt advanced control systems and precise transmission components, enabling high-precision motion control and cutting machining. Their positioning precision can reach the micron level, and the repeat positioning precision is even as high as the sub-micron level, being able to accurately machine the complex shapes and fine structures required by medical devices. For example, when machining miniature medical device components, CNC machine tools can precisely control the path of cutting tools and cutting parameters to ensure that every detail meets the design requirements, thus guaranteeing the performance and reliability of medical devices.Multi-Axis Linkage Machining Function

Many medical devices have three-dimensional curved surfaces or complex spatial structures that require multi-axis linkage machining to complete. CNC machine tools are usually equipped with three-coordinate, four-coordinate or even five-coordinate linkage systems, enabling the cutting tools to move simultaneously in multiple directions to achieve high-precision machining of complex curved surfaces. For example, when manufacturing dental implants, a five-axis linkage CNC machine tool can accurately machine the shape of the implant that perfectly matches the alveolar bone according to the patient's oral model, improving the success rate of the implantation surgery and the patient's comfort.Stability and Consistency

The mass production of medical devices requires that each product has the same quality and precision. CNC machine tools can maintain a stable machining state during long-term operation. Through precise programming and control, the machining parameters of each component are ensured to be the same, thus guaranteeing the quality stability and consistency of the products. This stability is crucial for medical device manufacturing as it can reduce the medical risks caused by differences in product quality.Flexible Machining Capability

With the continuous development and innovation of medical technology, the types and models of medical devices are constantly being updated. CNC machine tools have strong flexible machining capabilities and can quickly adapt to different machining tasks and product changes. By changing cutting tools, adjusting programming and machining parameters, CNC machine tools can easily machine various medical device components with different shapes and sizes to meet the diverse needs of the market for medical devices.

III. Application Examples of CNC Machine Tools in Medical Device Machining

Machining of Orthopedic Implants

Orthopedic implants such as artificial joints and bone plates are important products in medical devices. When CNC machine tools machine these implants, they can accurately machine the components that conform to the human anatomical structure according to the individual differences of patients and the design requirements of doctors. For example, by using the five-axis linkage machining function of CNC machine tools, titanium alloy materials can be machined into artificial joints with complex curved surfaces and micropore structures, improving the biocompatibility and fixation effect of the joints. At the same time, CNC machine tools can also machine special textures and coatings on the surface of the implants to enhance their binding force with bones and reduce the risk of postoperative loosening.Machining of Cardiovascular Devices

Cardiovascular devices such as heart stents and vascular interventional devices have extremely high requirements for machining precision and surface quality. CNC machine tools can machine cardiovascular stents with extremely small diameters and uniform wall thicknesses to ensure that the stents can successfully expand in the blood vessels and maintain good supporting force. During the machining process, CNC machine tools precisely control cutting parameters and tool paths to avoid scratches and burrs on the surface of the stents, reducing the risk of thrombosis formation in the blood vessels. In addition, CNC machine tools can also perform laser micro-machining on cardiovascular devices to achieve fine processing of the device surfaces, such as etching drug release grooves, to improve the treatment effect of the devices.Machining of Dental Devices

There are numerous types of medical devices in the dental field, including dental crowns, tooth bridges, implants, etc. CNC machine tools play an important role in the machining of dental devices. After obtaining the patient's oral model data through digital oral scanning technology, CNC machine tools can accurately machine personalized dental restorations according to these data. For example, when making dental crowns, CNC machine tools can machine ceramic materials into dental crowns that completely match the shape and color of the patient's teeth, making them have good aesthetics and functionality. At the same time, the high-speed cutting ability of CNC machine tools can significantly shorten the machining time, improve production efficiency, and meet the patient's need for rapid tooth restoration.

IV. Development Trends of CNC Machine Tools Technology in the Medical Device Machining Field

Intelligent Machining

With the development of artificial intelligence and big data technology, the intelligence level of CNC machine tools in medical device machining will continue to increase. Future CNC machine tools will have the ability to learn autonomously and optimize machining parameters. They will be able to automatically adjust the machining strategy according to the characteristics of materials, the wear condition of cutting tools, and real-time data during the machining process to achieve more efficient and precise machining. For example, by monitoring parameters such as cutting force, temperature, and vibration during the machining process through intelligent sensors, CNC machine tools can detect abnormal situations in time and make automatic compensations to improve the machining quality and stability.Application of Micro-Nano Machining Technology

As medical technology develops towards the microscopic field, the requirements for the microscopic structures and precision of medical devices are increasing. Micro-nano machining technology will become an important development direction of CNC machine tools in the medical device machining field. For example, by using nano-scale cutting tools and a high-precision positioning system, CNC machine tools can achieve nano-scale machining of medical device components, manufacturing micro-nano medical devices with higher performance and biocompatibility, such as nano-drug delivery systems, miniature sensors, etc.High-Speed Machining and Efficient Production

To meet the growing demands of the medical device market, improving production efficiency is an important goal of medical device manufacturing enterprises. The high-speed machining technology of CNC machine tools will continue to develop and improve. By increasing cutting speed, feed speed, and acceleration, the machining time will be shortened and production efficiency will be improved. At the same time, by combining with automated production lines and intelligent logistics systems, efficient mass production of medical devices will be achieved, reducing production costs and improving the enterprise's market competitiveness.Green Machining Technology

With the increasing awareness of environmental protection, the application of green machining technology in medical device machining will also receive more attention. CNC machine tools will adopt more environmental-friendly machining processes and materials to reduce the emissions of waste and pollutants during the machining process. For example, by using dry cutting technology instead of traditional wet cutting, the use and treatment costs of cutting fluid will be reduced, and the pollution to the environment will be reduced. In addition, by optimizing machining parameters and tool design, the energy utilization efficiency will be improved to achieve the goal of sustainable development.

Powered by:Market.HuaweiyunLogin