- | /

- | /

- | /

- | /

- | /

- | /

English

The Crucial Role of CNC Machine Tools in Automobile Manufacturing

2024-10-25 20:22

In the field of modern automobile manufacturing, CNC machine tools, like a behind-the-scenes hero, silently play a vital role, supporting the efficient and precise production of the entire automobile industry. Their presence runs through every stage of automobile manufacturing, from the processing of components to the assembly of the whole vehicle, and the precise operation and efficient running of CNC machine tools are indispensable.

I. Ensuring the Precision of Component Processing

The precision requirements for automobile components are extremely high, as any tiny error may affect the performance and safety of the automobile. CNC machine tools, with their excellent precision control capabilities, have become the preferred equipment for component processing. For example, the engine is the core component of an automobile, and the processing precision of its internal components such as pistons, crankshafts, and cylinder blocks directly relates to the power output, fuel economy, and reliability of the engine. CNC machine tools can process blank materials into components with strict dimensional tolerances and surface finish through precise programming and high-speed cutting technology. When processing pistons, CNC machine tools can precisely control the diameter, cylindricity, and surface roughness of the pistons to ensure the fitting precision between the pistons and the cylinder walls, thereby reducing the friction loss of the engine and improving its efficiency and lifespan. Similarly, when processing crankshafts, CNC machine tools can achieve complex curved shapes and high-precision journal sizes to ensure the balance and stability of the crankshaft during high-speed rotation, reducing the vibration and noise of the engine.

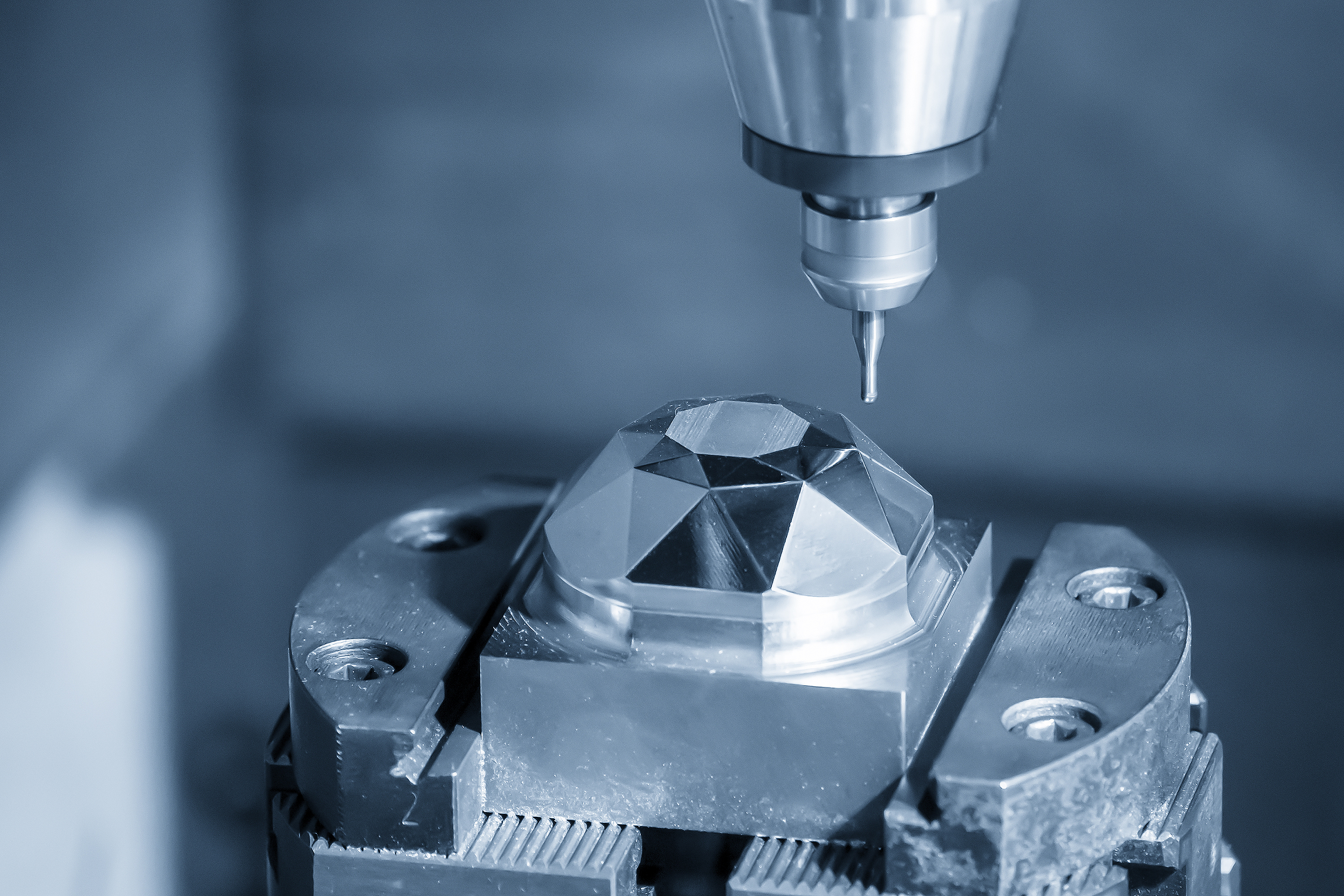

II. The Ability to Process Components with Complex Shapes

There are many components with complex shapes in automobiles, such as body panels, interior components, and chassis components. The design of these components not only needs to consider functionality and aesthetics but also meet the requirements of aerodynamics, ergonomics, and other aspects. The multi-axis linkage machining technology of CNC machine tools makes it possible to process these components with complex shapes. Taking body panels as an example, CNC machine tools can achieve high-precision machining of curved surfaces through five-axis or six-axis linkage. They can precisely control the movement trajectory of the cutting tool in space according to the pre-designed three-dimensional model and process the whole metal sheet into body panels with complex shapes and smooth lines, such as car doors, rooftops, and trunk lids. At the same time, CNC machine tools can complete the processing of multiple surfaces in one clamping, avoiding errors caused by multiple clampings and improving the processing precision and production efficiency. For the processing of interior components, CNC machine tools can utilize their flexible processing methods to produce various components with unique shapes and textures to meet consumers' demands for the comfort and personalization of automobile interiors.

III. Improving Production Efficiency

In the large-scale production industry like automobile manufacturing, production efficiency is an important manifestation of the competitiveness of enterprises. The high-speed cutting and automated processing capabilities of CNC machine tools have brought significant efficiency improvements to automobile manufacturing enterprises. High-speed cutting technology can greatly shorten the processing time of components and at the same time improve the surface quality of the processing, reducing subsequent polishing and finishing processes. The automatic tool changing system, automatic loading and unloading devices, and automated production lines equipped with CNC machine tools can achieve continuous and uninterrupted processing, reducing human intervention and downtime and increasing the utilization rate of equipment. For example, in the batch production of automobile components, CNC machine tools can automatically process according to the preset program, and one worker can monitor the operation of multiple machine tools simultaneously, thus greatly improving production efficiency and reducing production costs. In addition, CNC machine tools can achieve seamless connection from design to processing through integration with software systems such as Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM), further shortening the product development cycle and production preparation time, enabling automobile manufacturing enterprises to respond more quickly to market demands and launch new vehicle models.

IV. Guaranteeing Quality Stability

As a means of transportation related to people's lives and safety, the quality stability of automobiles is of crucial importance. CNC machine tools have a high degree of repeatability and consistency during the processing process, which can ensure the stable and reliable quality of each component. Through precise programming and strict process control, CNC machine tools can ensure that the parameters and precision of each processing remain the same, avoiding quality fluctuations caused by human factors. For example, when producing components of the automobile braking system, CNC machine tools can precisely control the size and surface quality of the brake discs and brake pads to ensure the stability of the friction force and braking effect between them. At the same time, CNC machine tools can monitor the quality parameters during the processing process, such as dimensional precision, shape precision, surface roughness, etc., in real time through online detection and monitoring systems. Once quality problems are detected, they can be adjusted and corrected in time to avoid the production of unqualified products. This guarantee of quality stability not only improves the overall quality level of automobiles but also enhances consumers' trust and satisfaction with automobile brands.

V. Adapting to the Rapid Development and Innovation Requirements of the Automobile Industry

With the continuous development and technological progress of the automobile industry, the manufacturing processes and design concepts of automobiles are constantly being updated and changed. CNC machine tools have a high degree of flexibility and extensibility and can quickly adapt to these changes and innovation requirements of the automobile industry. On the one hand, CNC machine tools can support new processing technologies and techniques by updating programming software and control algorithms. For example, with the rise of new energy vehicles, automobile manufacturing enterprises need to process more new materials and components, such as lithium battery components and electric vehicle motor housings. CNC machine tools can adapt to the processing requirements of these new materials by adjusting processing parameters and tool selection, providing technical support for the development of new energy vehicles. On the other hand, the modular design and open control system of CNC machine tools enable enterprises to carry out customized transformation and upgrading according to their own production requirements, adding new functions and equipment, and improving the automation degree and intelligence level of the production line. This adaptability enables CNC machine tools to always keep up with the development pace of the automobile industry and provide continuous technical support and innovation power for automobile manufacturing enterprises.

In conclusion, CNC machine tools play an indispensable and crucial role in automobile manufacturing. With their high precision, high ability to process complex shapes, high efficiency, high quality stability, and strong adaptability, they provide a solid technical guarantee for the development of the automobile manufacturing industry. With the continuous progress of science and technology and the continuous improvement of the manufacturing technology requirements of the automobile industry, CNC machine tools will also be continuously innovated and developed, further enhancing their role and value in automobile manufacturing and promoting the automobile industry to move to a higher level.

name:

Message:

Verification code:

submit

Comment

Powered by:Market.HuaweiyunLogin