- | /

- | /

- | /

- | /

- | /

- | /

Maintenance of CNC Machine Tools: The Key to Ensuring High-Precision Production

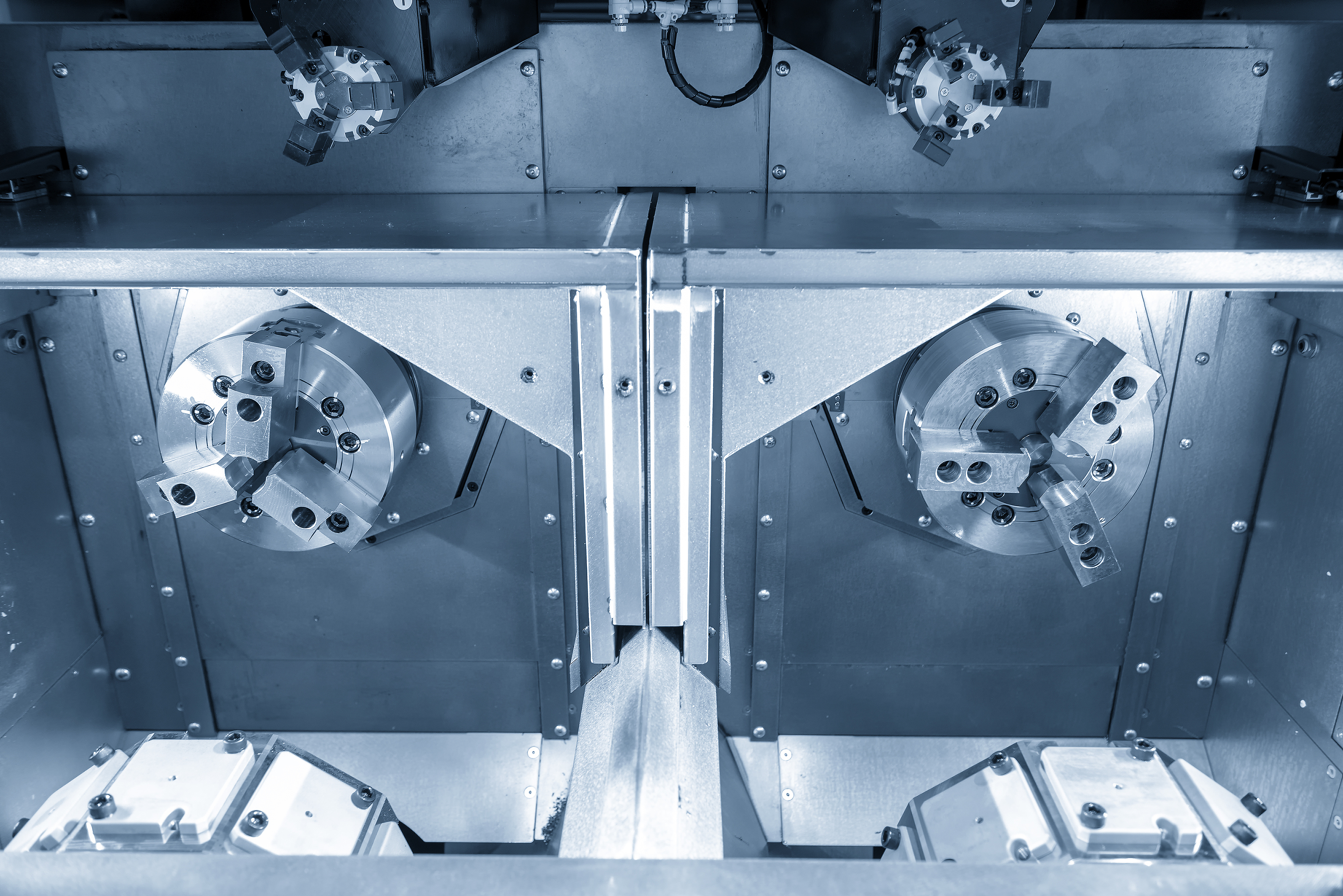

In modern manufacturing, CNC machine tools have become core equipment due to their high precision, high efficiency, and high degree of automation. However, to ensure that CNC machine tools always maintain good performance and exert their maximum value, we must attach great importance to their maintenance.

Cleaning

Keeping CNC machine tools clean is an important part of daily maintenance. After work every day, use a clean rag to wipe the surface of the machine tool to remove dust, oil stains, chips and other debris. Especially for key parts such as guide rails and lead screws, ensure that there is no residual impurity to avoid affecting the precision and movement smoothness of the machine tool.Lubrication

Timely lubrication can reduce friction between machine tool parts, reduce wear, and extend the service life of the machine tool. According to the requirements of the machine tool manual, add oil and lubricate each lubrication point regularly. At the same time, pay attention to observing the liquid level and quality of the lubricating oil and replace the deteriorated lubricating oil in time.

Inspection

Before starting the machine every day, conduct a comprehensive inspection of the machine tool. Including checking whether the connections of various parts are firm, whether the transmission system is normal, and whether the cutting tool is worn. Deal with problems in time to avoid failures during the processing process.

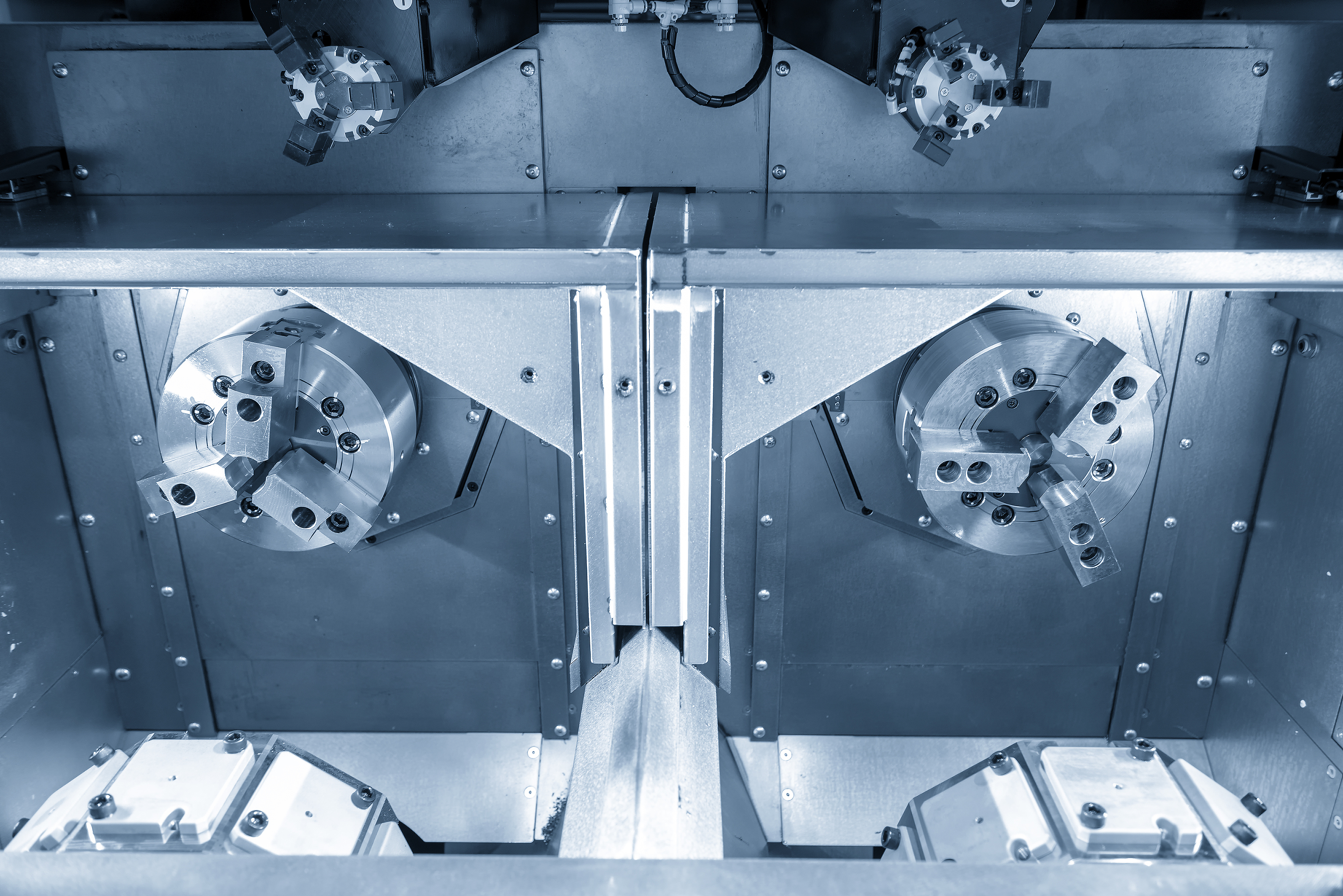

II. Regular Maintenance

Precision adjustment

After the CNC machine tool is used for a period of time, its precision may decline. Therefore, it is necessary to adjust the precision of the machine tool regularly. Including detecting and adjusting the positioning accuracy, repeat positioning accuracy, and backlash of the coordinate axes to ensure that the processing accuracy of the machine tool meets the requirements.Electrical system maintenance

The electrical system is the core part of the CNC machine tool, and regular maintenance of it is crucial. Check whether the wiring in the electrical cabinet is loose and whether the electrical components are working properly. At the same time, regularly clean the dust in the electrical cabinet to prevent electrical failures caused by dust accumulation.Cooling system maintenance

The normal operation of the cooling system has an important impact on the processing quality and tool life of the CNC machine tool. Regularly check whether the pipeline of the cooling system is unobstructed and whether the liquid level and quality of the coolant meet the requirements. Replace the deteriorated coolant in time to ensure good cooling effect.

Operator training

Operators of CNC machine tools should receive professional training and be familiar with the operation methods and maintenance knowledge of machine tools. Operate strictly in accordance with the operating procedures to avoid machine tool failures caused by improper operation.Environmental requirements

CNC machine tools should be installed in a dry and well-ventilated environment, avoiding direct sunlight and humidity. At the same time, keep the environment around the machine tool clean and avoid the accumulation of debris affecting the normal operation of the machine tool.Maintenance records

Establish a perfect maintenance record system and record the maintenance situation of the machine tool in detail. Including information such as the time, content, and replaced parts of maintenance, so as to facilitate future query and analysis of the running status of the machine tool.

Powered by:Market.HuaweiyunLogin