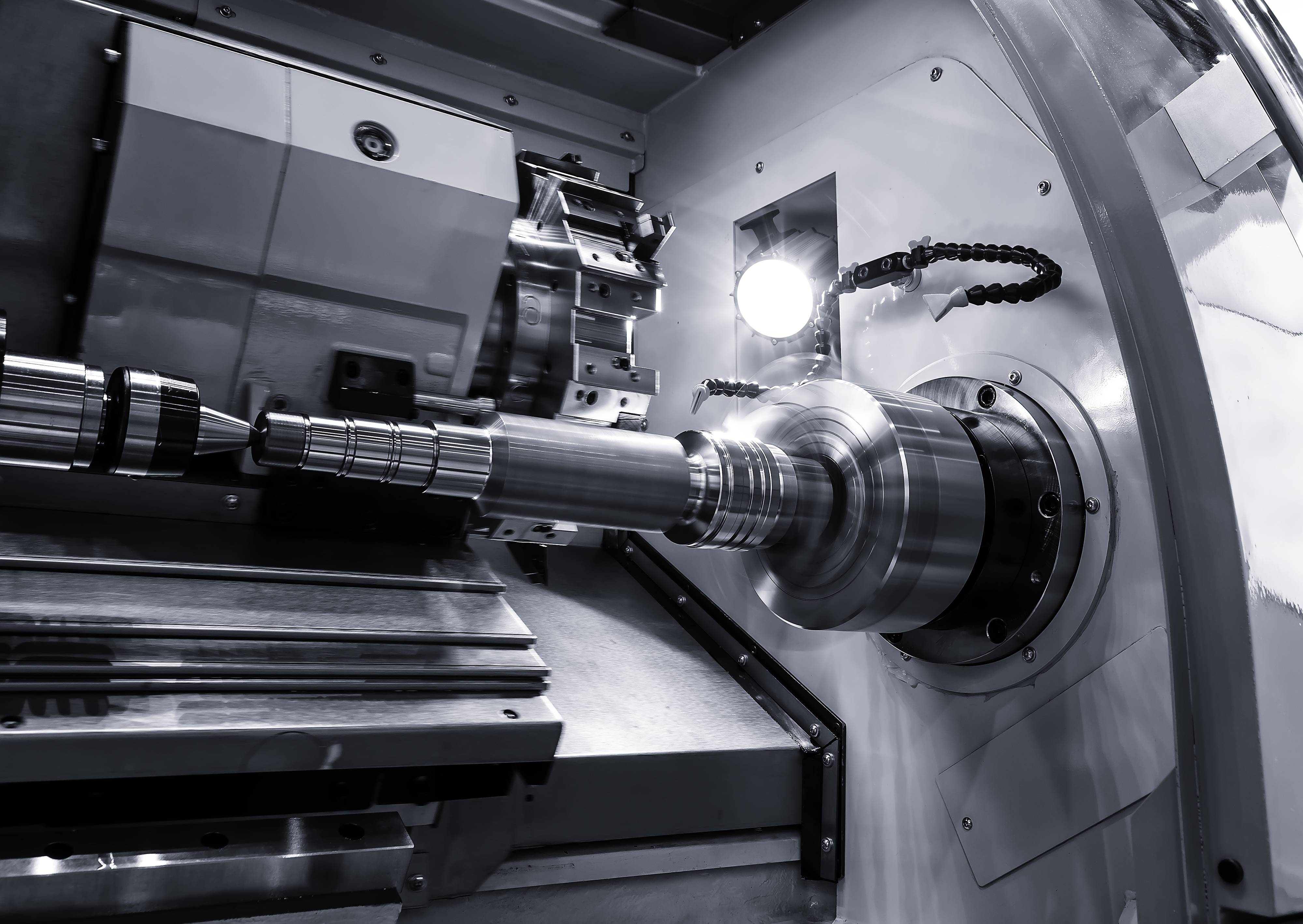

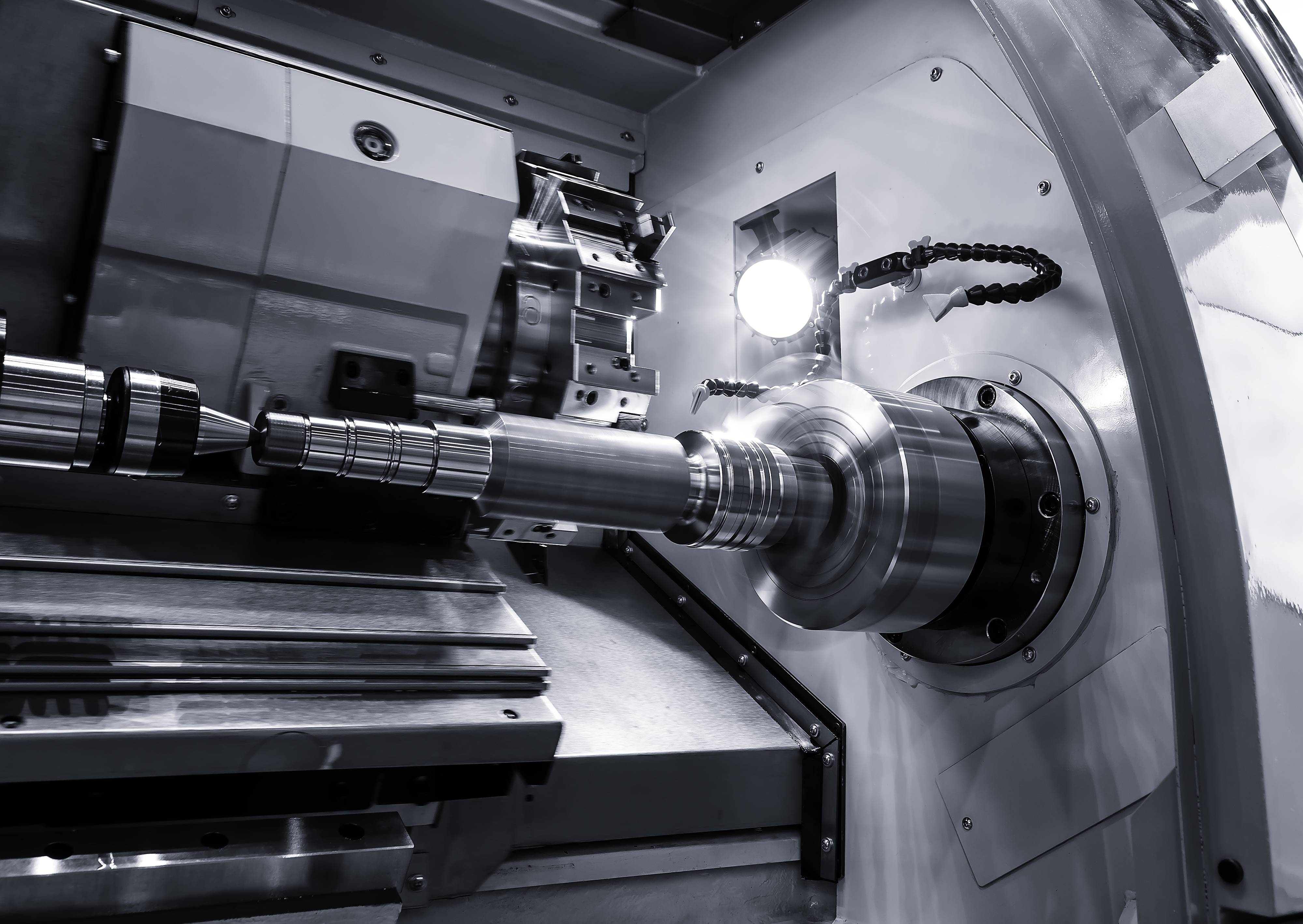

The basic components of CNC machine tools

A CNC lathe consists of a CNC device, a bed body, a spindle box, a tool holder feed system, a tailstock, a hydraulic system, a cooling system, a lubrication system, a chip conveyor, and other components.

CNC lathes are divided into two types: vertical CNC lathes and horizontal CNC lathes.

Vertical CNC lathe is used for turning large diameter disc parts.

Horizontal CNC lathe is used for turning machining of long or small disc parts with axial dimensions.

Horizontal CNC lathes can be further divided into economical CNC lathes, ordinary CNC lathes, and turning machining centers according to their functions.

Economic CNC lathe: A simple CNC lathe formed by modifying the turning feed system of a regular lathe using a stepper motor and a microcontroller. The cost is relatively low, the degree of automation and functionality are relatively poor, and the turning accuracy is not high. It is suitable for turning low demand rotary parts.

Ordinary CNC lathe: A CNC lathe specially designed in structure according to the requirements of turning machining, equipped with a universal CNC system. The CNC system has strong functions, high degree of automation and machining accuracy, and is suitable for turning general rotary parts. This CNC lathe can simultaneously control two coordinate axes, namely the x-axis and z-axis.

turning center

Turning machining center: On the basis of ordinary CNC lathes, C-axis and power head are added, and more advanced machine tools also have tool libraries, which can control the X, Z, and C coordinate axes. The linkage control axis can be (X, Z), (X, C), or (Z, C). Due to the addition of C-axis and milling power head, the machining function of this CNC lathe is greatly enhanced. In addition to general turning, it can also perform radial and axial milling, surface milling, drilling of holes and radial holes whose center line is not at the center of rotation of the part, etc.

Hydraulic chuck and hydraulic tailstock

Hydraulic chuck is an important accessory for clamping workpieces during CNC turning, and ordinary hydraulic chuck can be used for general rotary parts; For parts that are not cylindrical in shape, a specialized chuck is required; When directly processing parts with bar material, a spring chuck is required. For parts with a large ratio of axial and radial dimensions, it is necessary to use a movable tip installed on the hydraulic tailstock to support the tail end of the part, in order to ensure correct machining of the part. There are ordinary hydraulic tailstock and programmable hydraulic tailstock.

Universal knife holder

CNC lathes can be equipped with two types of tool holders:

① Specialized tool holder: Developed by the lathe manufacturer themselves, the tool holder used is also specialized. The advantage of this type of knife holder is its low manufacturing cost, but it lacks universality.

② Universal tool holder: A tool holder produced according to certain universal standards (such as VDI, German Institute of Engineers), and CNC lathe manufacturers can choose and configure it according to the functional requirements of the CNC lathe.

Milling power head

Installing milling power heads on the tool holder of a CNC lathe can greatly expand the machining capacity of the CNC lathe. For example, using milling power heads for axial drilling and milling axial grooves.

Tools for CNC lathes

When machining parts on a CNC lathe or turning center, the position of the tool on the tool holder should be arranged reasonably and scientifically according to the structure of the lathe tool holder and the number of tools that can be installed. Attention should be paid to avoiding interference between the tool and the machine tool, tool and workpiece, and tool interactions when the tool is stationary or working.

Machine tool composition

The host is the main body of a CNC machine tool, including mechanical components such as the machine body, columns, spindle, and feed mechanism. He is a mechanical component used to complete various cutting processes.

Numerical control device is the core of numerical control machine tools, including hardware (printed circuit board, CRT display, key box, paper tape reader, etc.) and corresponding software, used to input digital part programs, store input information, transform data, perform interpolation operations, and implement various control functions.

The driving device is the driving component of the CNC machine tool actuator, including the spindle driving unit, feed unit, spindle motor, and feed motor. He drives the spindle and feed through an electrical or electro-hydraulic servo system under the control of a numerical control device. When several feed rates are linked, the machining of positioning, straight lines, planar curves, and spatial curves can be completed.

Auxiliary devices, some necessary supporting components of index controlled machine tools, used to ensure the operation of CNC machine tools, such as cooling, chip removal, lubrication, lighting, monitoring, etc. It includes hydraulic and pneumatic devices, chip removal devices, exchange workbenches, CNC turntables, and CNC indexing heads, as well as cutting tools and monitoring and detection devices.

Programming and other auxiliary equipment can be used for programming, storage, etc. of parts outside the machine.

Since the Massachusetts Institute of Technology developed the world's first CNC machine tool in 1952, CNC machine tools have been widely used in the manufacturing industry, especially in the automotive, aerospace, and military industries. CNC technology has developed rapidly in both hardware and software aspects.