Principles for selecting machine tools

preparation in advance

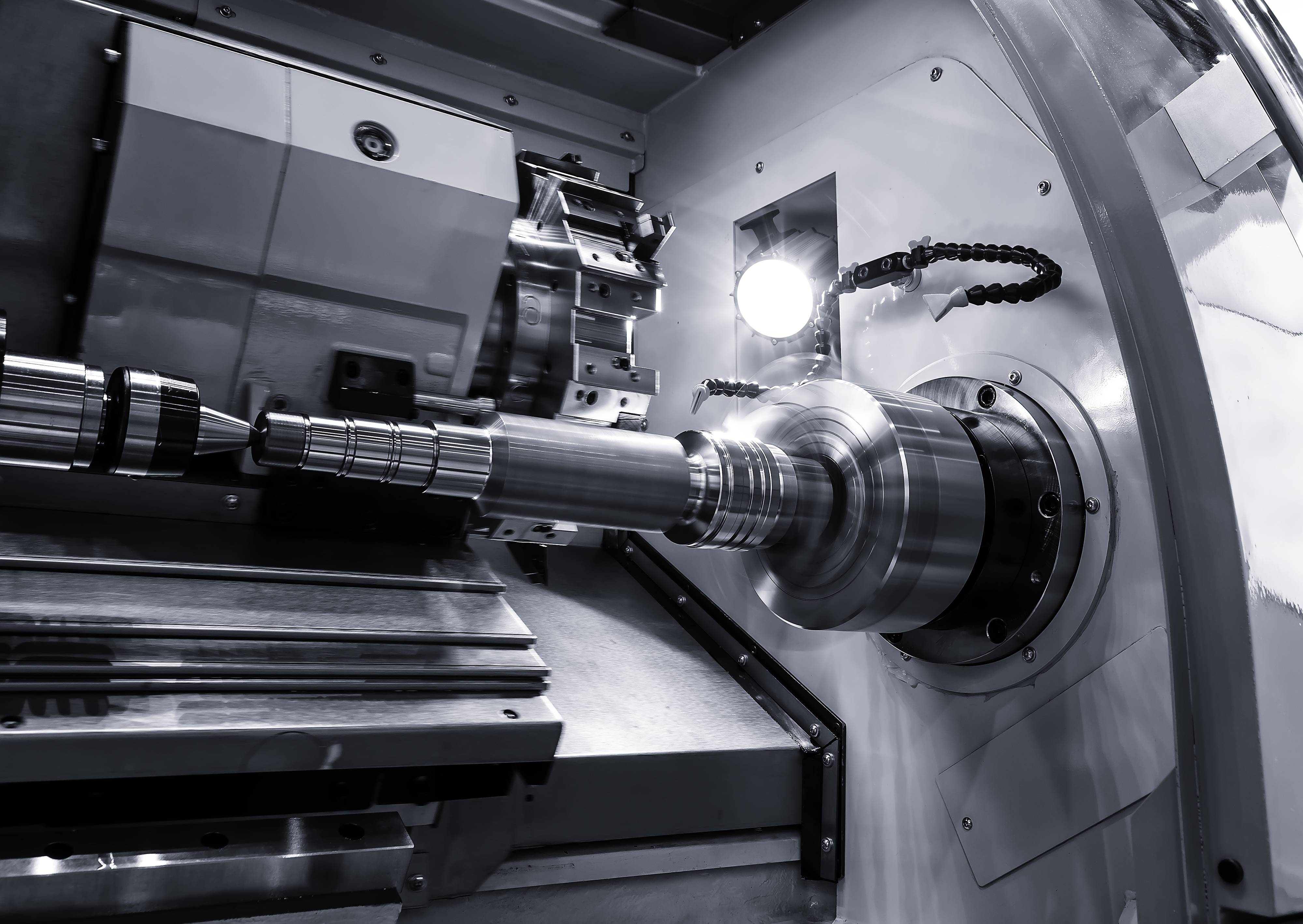

The determination of the process requirements for typical parts and the batch size of processed workpieces, as well as the formulation of the functions that a CNC lathe should have, is a prerequisite for making early preparations and selecting a CNC lathe reasonably: meeting the process requirements of typical parts.

The process requirements for typical parts mainly include the structural dimensions, processing range, and precision requirements of the parts. Select the control accuracy of the CNC lathe based on the precision requirements, namely the dimensional accuracy, positioning accuracy, and surface roughness of the workpiece. Choose based on reliability, which is the guarantee for improving product quality and production efficiency. The reliability of a CNC machine tool refers to its ability to operate stably for a long time without failure under specified conditions. The average time between failures is long, and even in the event of a malfunction, it can be quickly restored and put back into use. Choose machine tools with reasonable structure, excellent manufacturing, and mass production. Generally, the more users there are, the higher the reliability of the CNC system.

Machine tool accessories and cutting tools

Machine tool accessories, spare parts, and their supply capacity, as well as cutting tools, are very important for CNC lathes and turning centers that have already been put into production. When choosing a machine tool, careful consideration should be given to the compatibility of the cutting tools and accessories.

Control system

Manufacturers generally choose products from the same manufacturer and should at least purchase control systems from the same manufacturer, which brings great convenience to maintenance work. It is a wise choice for teaching units to use different systems and equip them with various simulation software due to the need for students to be well-informed.

Performance price ratio selection

Ensure that the functionality and accuracy are not idle or wasted, and do not choose functions that are unrelated to your own needs.

Protection of machine tools

When needed, the machine tool can be equipped with fully enclosed or semi enclosed protective devices and automatic chip removal devices.

When choosing CNC lathes and turning centers, the above principles should be comprehensively considered.