CNC Machine Tools: The Precise Dancers in Modern Manufacturing

Entering the workshop of CNC machine tools, the first thing that catches the eye is row upon row of neatly arranged machine tools full of a sense of technology. They are like steel warriors standing at the ready, quietly waiting for commands. When the operator presses the start button, a wonderful manufacturing journey quietly begins.

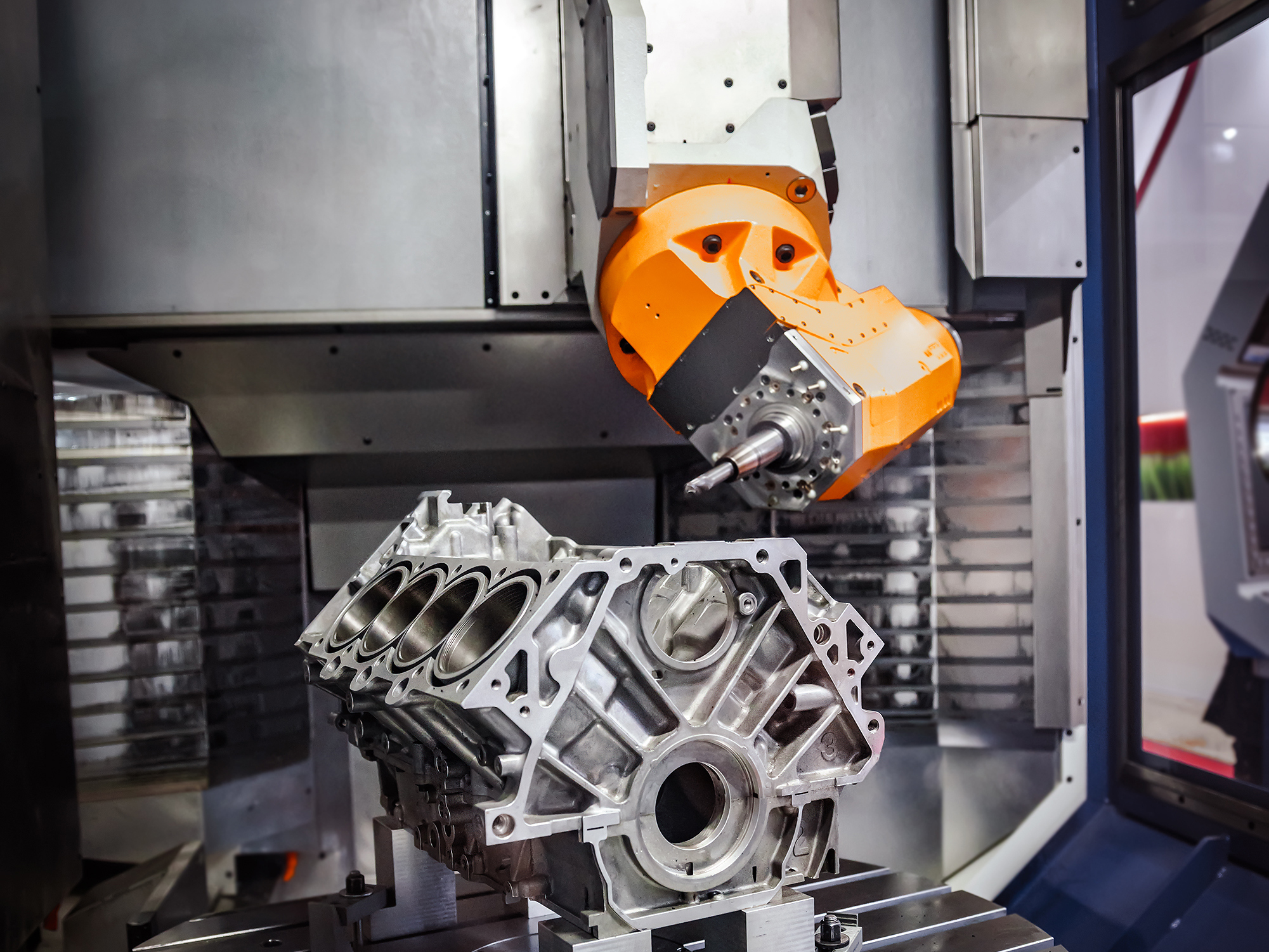

The core of CNC machine tools lies in their advanced control system. This is like the brain of a dancer, precisely commanding every movement. Through pre-written program codes, the control system can transform complex processing techniques into coordinated movements of various parts of the machine tool. Under the drive of the spindle, the cutting tool rotates at high speed, like the light ribbon in the dancer's hand, passing across the surface of the workpiece according to the set trajectory. Each cut contains precise control of force and angle to ensure that the processed parts reach extremely high precision requirements. Compared with traditional machine tools, CNC machine tools can achieve multi-axis linkage, which enables it to complete more complex tasks such as curved surface processing. For example, in the manufacturing of aerospace components, those structural parts with complex shapes can be easily handled by CNC machine tools to process high-precision products that meet strict standards.

Not only that, but the high efficiency of CNC machine tools is also one of its remarkable features. It can achieve automated continuous processing, greatly reducing the auxiliary time in the processing process. The operator only needs to monitor and make necessary interventions on the side. This not only improves production efficiency but also reduces labor costs. Moreover, the flexible processing ability of CNC machine tools enables it to quickly adapt to the processing needs of different parts. By simply changing the program and cutting tool, various parts with different shapes, sizes, and precision requirements can be processed on the same machine tool, just like a versatile dancer can easily switch between different dance styles.