In modern industrial production, CNC machine tools play a crucial role. With high precision, high efficiency, and high stability, they provide strong support for manufacturing in various fields. Customized CNC machine tools, on the other hand, are designed, manufactured, and debugged by professional machine tool manufacturers according to specific production needs, providing enterprises with more accurate and efficient solutions.I. What are customized CNC machine tools?

Customized CNC machine tools are machine tools designed, manufactured, and debugged by professional machine tool manufacturers according to the specific requirements of customers. These requirements may include the size, shape, material, precision requirements, and production batch of processed parts. Compared with standard CNC machine tools, customized CNC machine tools are more in line with the actual production needs of customers and can improve production efficiency, reduce costs, and improve product quality.

II. Advantages of customized CNC machine tools

Meet specific processing needs

Different enterprises will face different processing needs in the production process. Customized CNC machine tools can be designed according to the specific requirements of enterprises, such as processing parts with special shapes, using specific tools or fixtures, and meeting high-precision processing requirements. This can ensure that the machine tool can fully exert its performance in the production process and improve processing efficiency and quality.

Improve production efficiency

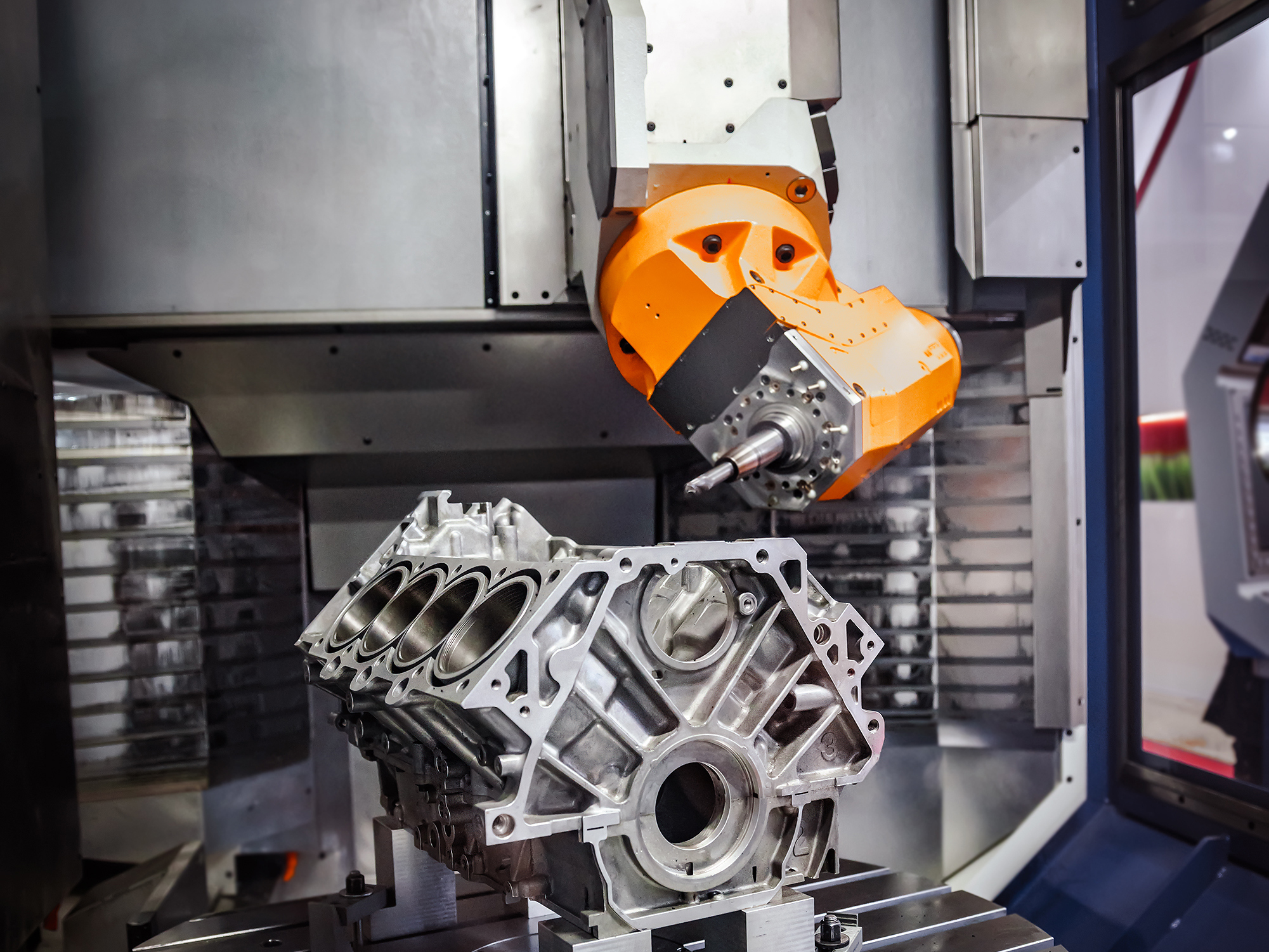

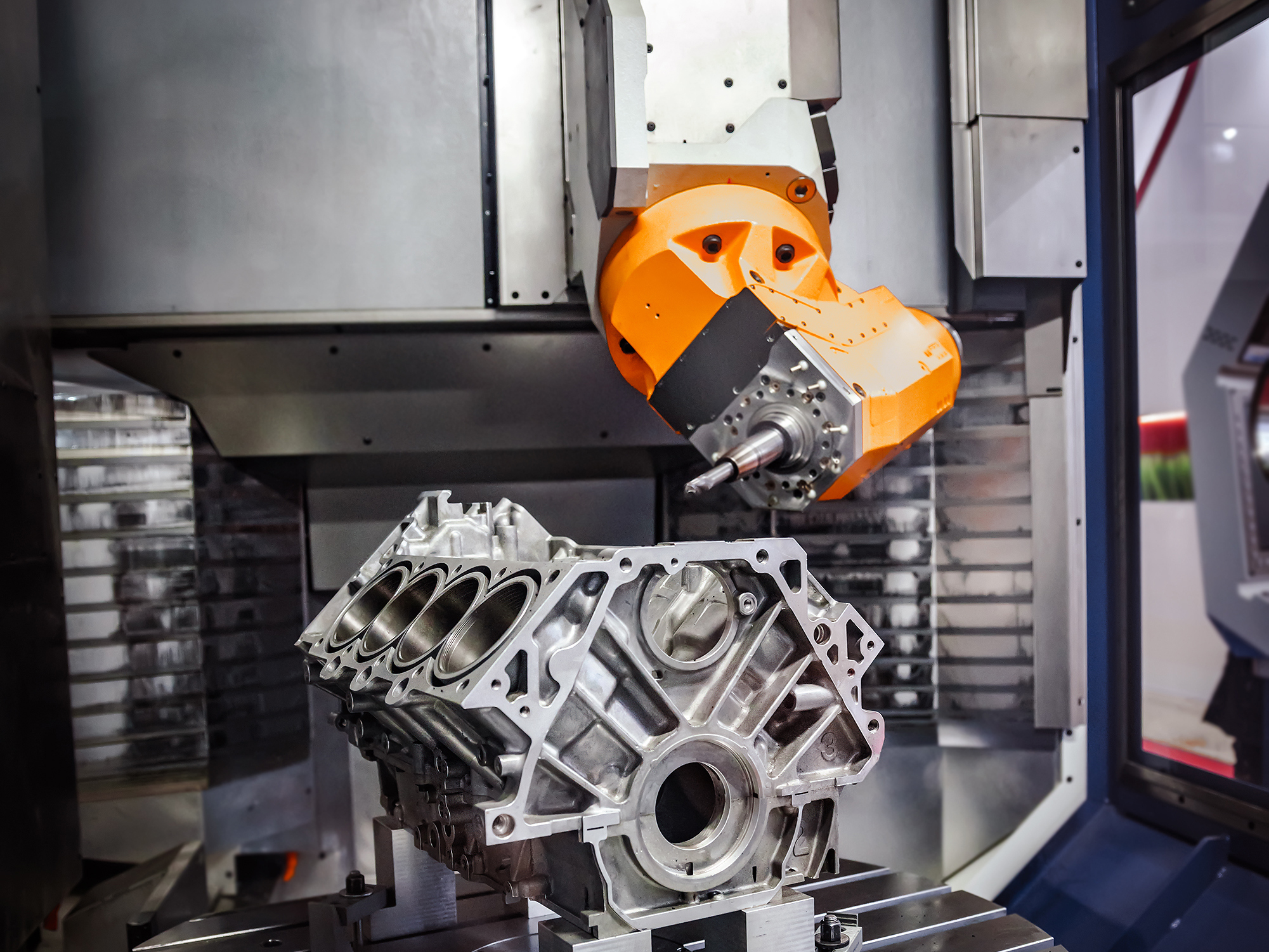

Customized CNC machine tools can be optimized according to the production process of enterprises to reduce auxiliary time in the processing process and improve production efficiency. For example, an automated loading and unloading system and tool change system can be designed to reduce manual intervention and improve the degree of automation in production.

Reduce costs

Although the price of customized CNC machine tools is usually higher than that of standard CNC machine tools, in the long-term production process, it can bring lower costs to enterprises. Customized CNC machine tools can be optimized according to the production needs of enterprises to reduce unnecessary functions and configurations and lower the purchase cost of machine tools. At the same time, since customized CNC machine tools are more in line with the actual production needs of enterprises, they can improve production efficiency and product quality and reduce scrap rates and maintenance costs.

Improve product quality

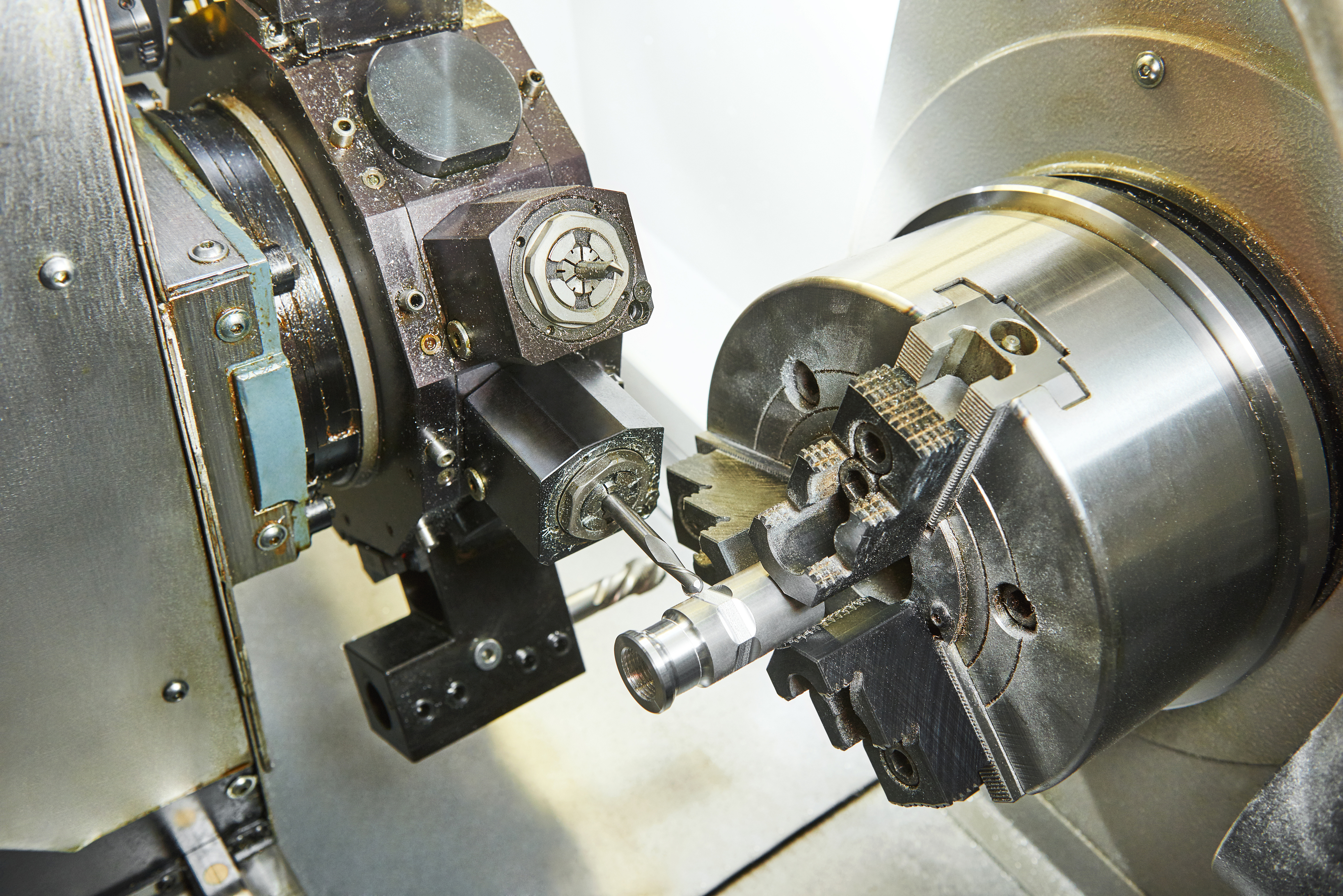

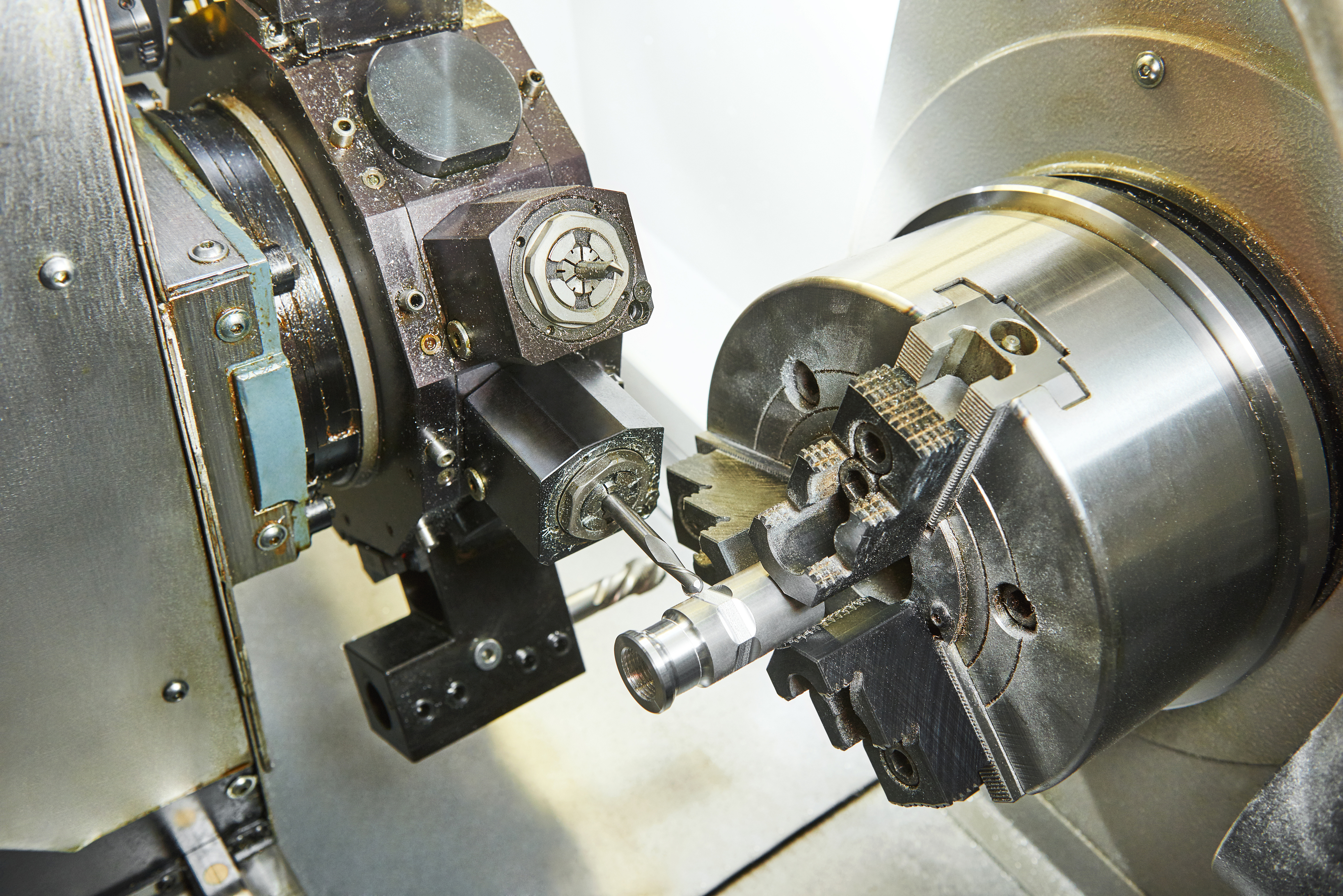

Customized CNC machine tools can be designed according to the product quality requirements of enterprises to ensure the precision and stability of the processing process. For example, high-precision guide rails, screws, spindles and other components can be used to improve the processing precision of machine tools; advanced control systems and sensors can be used to monitor the parameters in the processing process in real time to ensure the stability of product quality.

III. Design process of customized CNC machine tools

Demand analysis

The machine tool manufacturer will first communicate with the customer to understand the customer's processing needs, production process, product quality requirements, etc. Through the analysis of these information, the design scheme of the customized CNC machine tool is determined.

Formulation of design scheme

According to the results of demand analysis, the design team of the machine tool manufacturer will formulate a detailed design scheme. This scheme includes the structural design of the machine tool, the design of the control system, the design of tools and fixtures, etc. The design scheme needs to be confirmed by the customer before proceeding to the next step.

Manufacturing and debugging

After the design scheme is determined, the machine tool manufacturer will start the manufacturing and debugging work of the machine tool. This process needs to be carried out in strict accordance with the design scheme to ensure that the quality and performance of the machine tool meet the requirements. During the manufacturing and debugging process, the machine tool manufacturer will also communicate with the customer to solve the problems in time.

Delivery and training

When the manufacturing and debugging of the machine tool are completed, the machine tool manufacturer will deliver the machine tool to the customer and conduct training. The training content includes the operation method and maintenance method of the machine tool. Ensure that customers can use and maintain the machine tool correctly and improve the service life and performance of the machine tool.

IV. Application fields of customized CNC machine tools

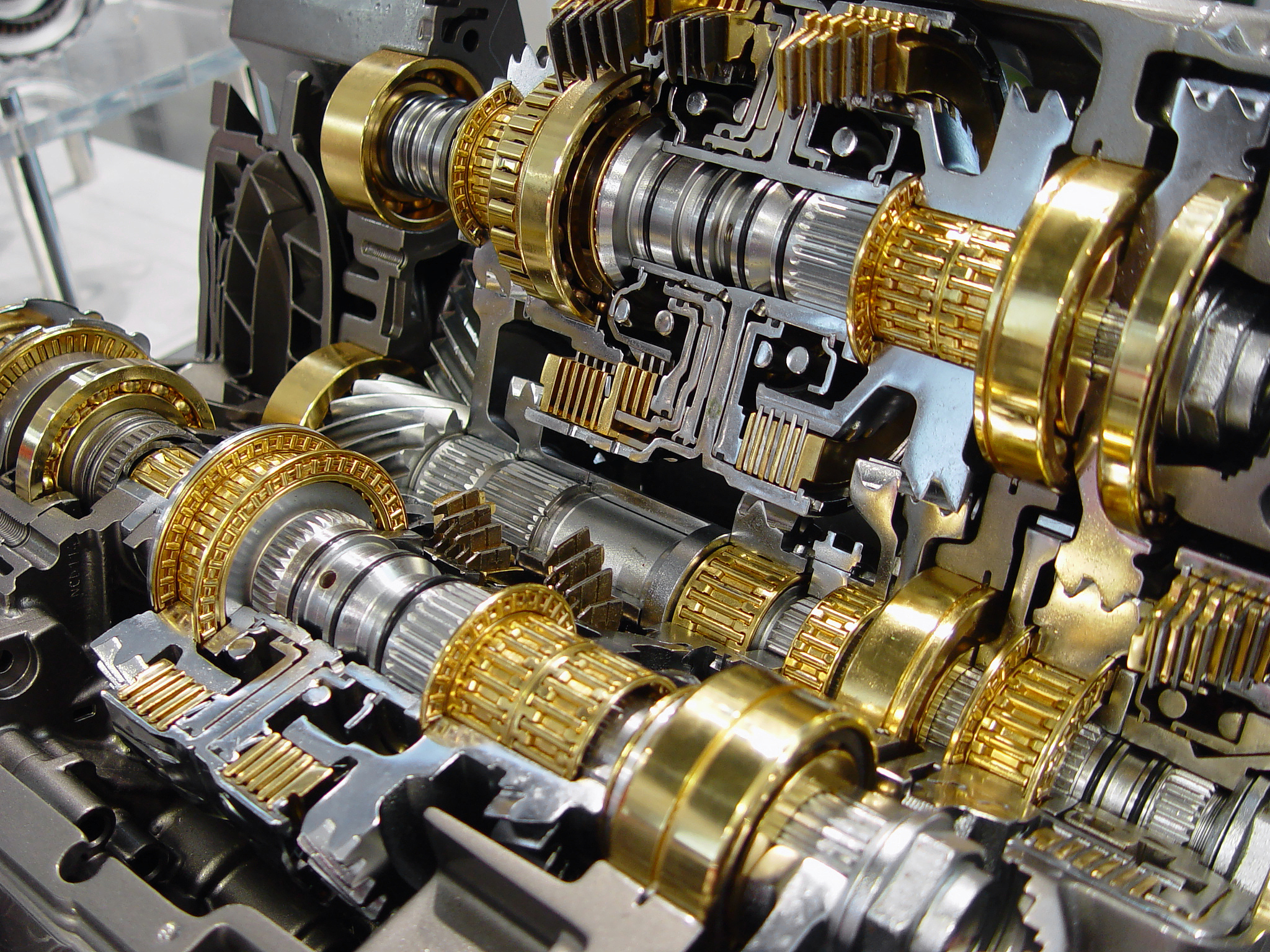

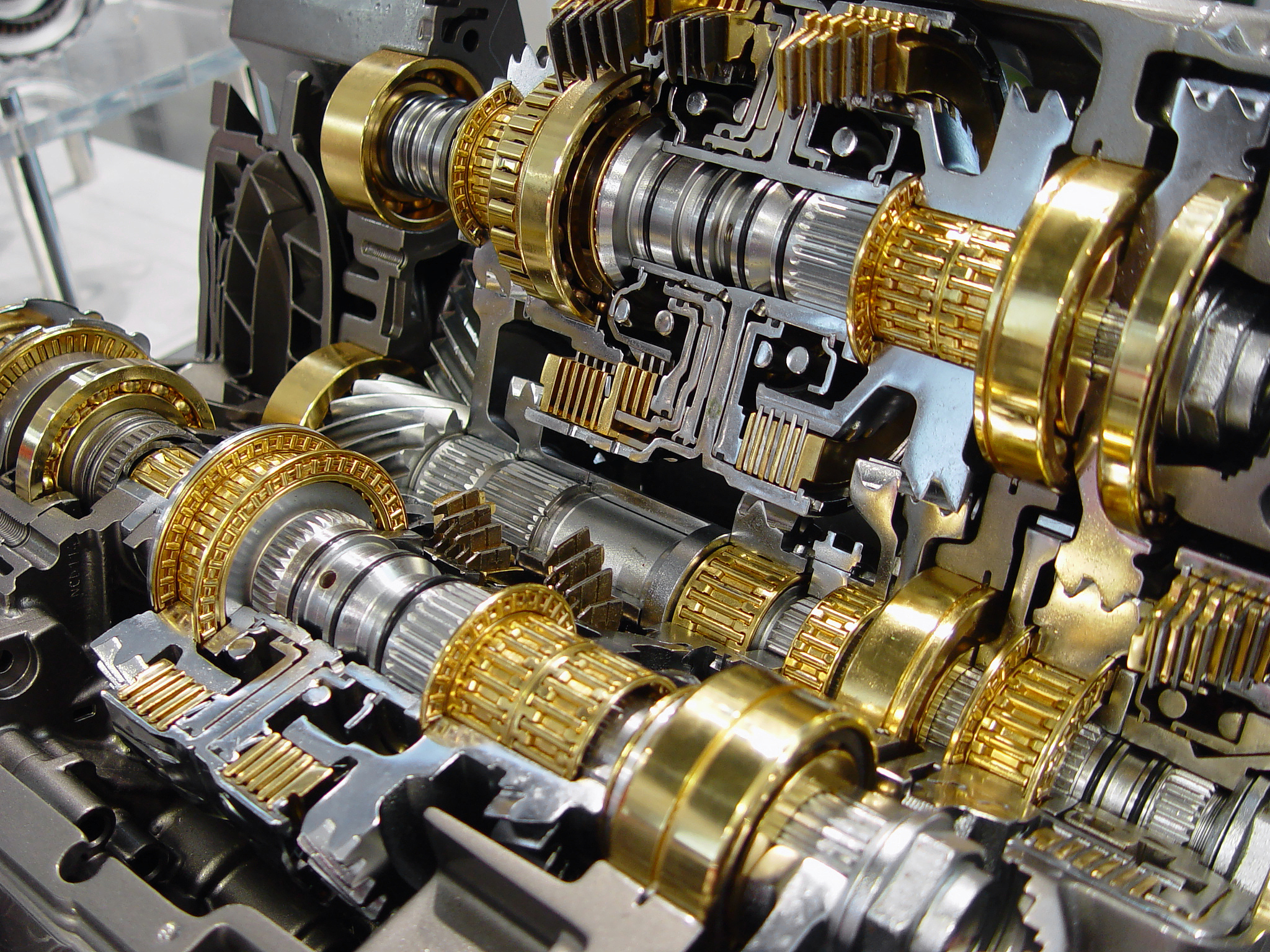

Customized CNC machine tools are widely used in fields such as aerospace, automobile manufacturing, mold manufacturing, and electronics manufacturing. In these fields, enterprises usually need to process high-precision and complex-shaped parts, and customized CNC machine tools can meet these needs. For example, in the aerospace field, customized CNC machine tools can process high-precision parts such as aircraft engine blades and turbine disks; in the automobile manufacturing field, customized CNC machine tools can process complex-shaped parts such as automobile engine cylinders and cylinder heads; in the mold manufacturing field, customized CNC machine tools can process high-precision mold parts and improve the quality and service life of molds.

In conclusion, customized CNC machine tools are important equipment in modern industrial production. They can be personalized designed and manufactured according to the specific needs of enterprises, providing enterprises with more accurate and efficient solutions. When choosing customized CNC machine tools, enterprises need to select professional machine tool manufacturers according to their actual needs to ensure that the quality and performance of the machine tools meet the requirements.