CNC Machines: Precision Engineering Marvels

In the realm of modern manufacturing, Computer Numerical Control (CNC) machines have emerged as true game-changers. These sophisticated devices are at the forefront of industrial progress, enabling the production of highly accurate and complex parts with ease.

I. What Are CNC Machines?

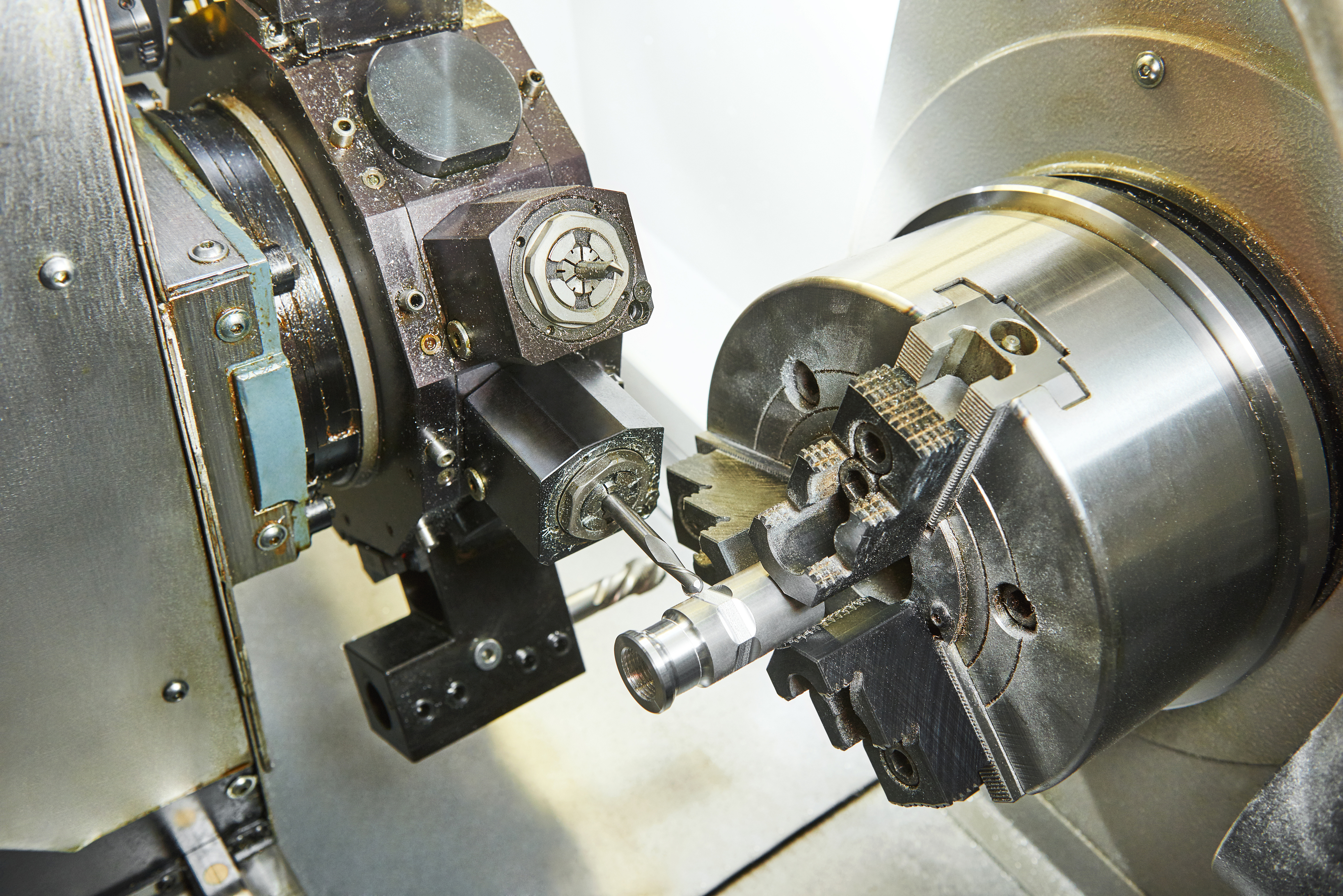

A CNC machine is a computer-controlled tool that can cut, shape, and finish materials with extraordinary precision. Unlike traditional machines that rely on manual operation, CNC machines follow a set of programmed instructions to perform specific tasks. This programmability gives them a significant advantage in terms of accuracy and repeatability.

The components of a CNC machine typically include a computer control unit, a spindle that holds the cutting tool, a worktable to hold the material being processed, and various motors and drives to move the cutting tool and worktable in precise directions. The computer control unit is the brain of the machine, interpreting the programmed instructions and sending signals to the motors and drives to execute the desired movements.

II. Key Features of CNC Machines

One of the key features of CNC machines is their ability to perform multiple operations in a single setup. This not only saves time but also reduces the risk of errors that can occur when transferring parts between different machines. For example, a CNC milling machine can perform operations such as drilling, boring, and threading on a single workpiece, all without the need for manual intervention.

III. Industries Utilizing CNC Machines

CNC machines are used in a wide range of industries, including aerospace, automotive, electronics, and medical.

· Aerospace Industry: In the aerospace industry, for instance, CNC machines are used to manufacture critical components such as engine parts and airframe structures. The high precision and reliability of these machines ensure that the parts meet the strict quality standards required for flight safety.

· Automotive Industry: In the automotive industry, CNC machines are employed to produce engine blocks, transmission parts, and other complex components. The ability to mass-produce parts with consistent quality is essential for meeting the demands of the automotive market.

· Electronics Industry: The electronics industry also benefits from CNC machines, which are used to manufacture printed circuit boards and other precision components. The small size and high density of electronic components require extremely accurate machining, which CNC machines are well-suited to provide.

· Medical Industry: Medical devices are another area where CNC machines play a crucial role. Components such as implants and surgical instruments require precise dimensions and smooth surfaces to ensure patient safety and effectiveness. CNC machines can produce these parts with the required level of precision and quality.

IV. Conclusion

In conclusion, CNC machines are essential tools in modern manufacturing. Their ability to produce complex parts with high precision and repeatability has revolutionized the way products are made. As technology continues to advance, we can expect CNC machines to become even more sophisticated and capable, further driving the growth of industries around the world.